As an experienced contract packer, we have been setting the industry benchmark for years. Innovative ideas and convincing full service help us maintain and expand our advantage in the market.

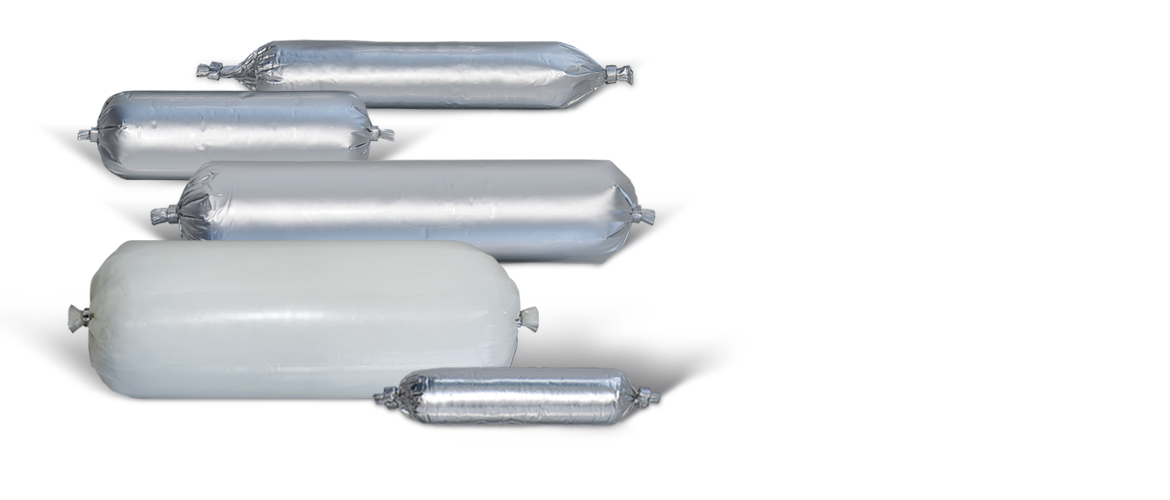

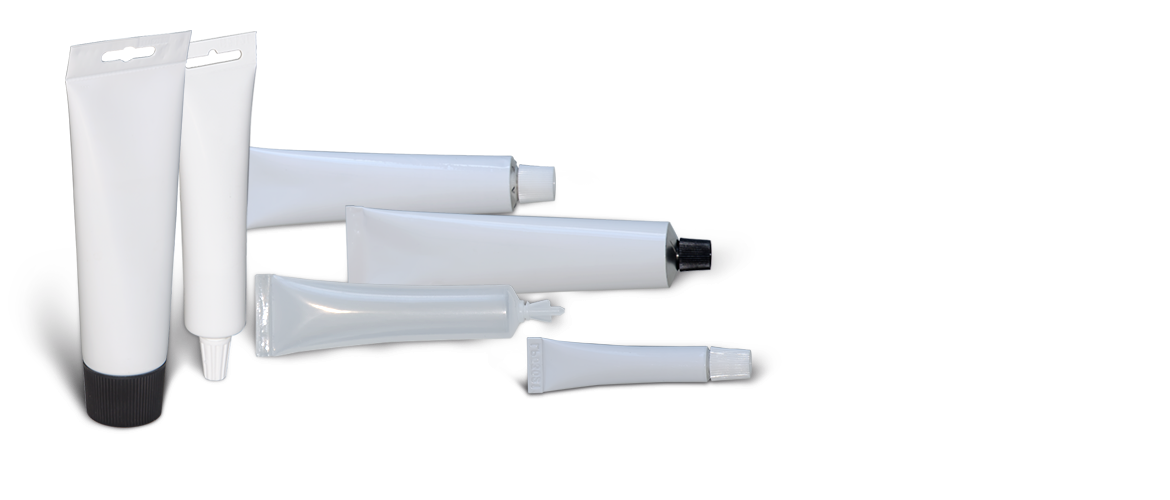

Filling a wide range of packaging types is the core competence of Lohnpack. Additional packaging and assembly complete our range of services and have enabled us to establish Lohnpack as a leading company in the contract packaging industry.

German efficiency for international customers. Obviously, all work is carried out following the valid regulations and directives. The packaging professionals at Lohnpack work according to the following acts:

- Pre-packaged goods act (FPVO)

- Measuring and gauging act (Mess EG)

- Chemicals act (ChemG)

- European agreement on international movement of hazardous goods on streets (ADR)

Lohnpack customers are on the safe side.

We regularly calibrate weighing scales, including all legally prescribed documentation. On demand, the documentation can be provided to our customers.

We continuously modernize our machinery because efficiency is vital in contract filling. Most plants are fully automated. So-called “closed systems” allow for airless filling. Especially with moisture-sensitive or 2-component filling materials, this is a substantial part of ensuring high quality.

All parts of a machine that may come into contact with the product being processed consist of stainless steel or are coated with a special material. Cross-contamination is absolutely impossible because all parts coming into contact with the filling material will be dismantled and cleaned thoroughly after every single filling process.

The processing and filling of materials (whether liquid, highly viscous, flammable or moisture-sensitive) is carried out via gravity feed or via drum and Hobbock presses.