As one of Europe’s leading packaging service providers, Lohnpack is the packaging specialist of choice for ampoules, including:

- Glass ampoules

- Ampoules to be opened by breaking off the neck

- Ampoules to be opened by sawing off the neck>

- Syringe ampoules

- Dry ampoules

- Flat bottom tubes

Once again, the high degree of automation employed at Lohnpack proves to be a sound basis for excellence and precision for our packaging offers. We can ramp up our production to a daily throughput of 120,000 glass ampoules – at our usual, controlled quality!

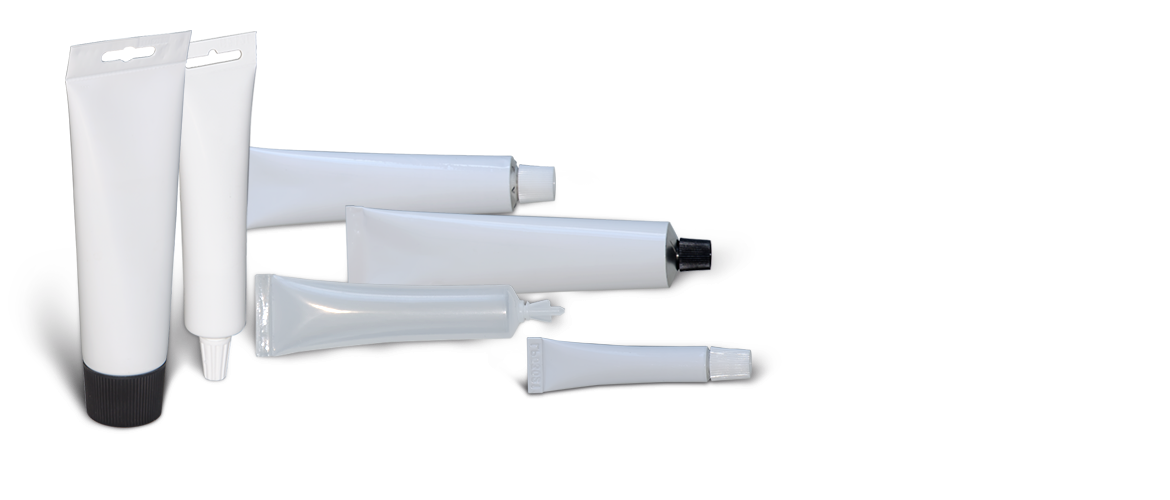

We can fill clear or brown flat bottom tubes of varied diameters and wall thicknesses fully automatically. In particular, we can fill chemical and technical materials in the range of 1.0 ml to 20 ml with high precision at a tolerance of ±0.15 ml.

We ensure adherence to these tolerances through regular, extensive weighing procedures and the corresponding documentation. We also safely and expertly handle flammable filling materials that contain solvents.

Due to optimally coordinated filling and measuring technology, filling primers with a defined solid content is not a problem.

Lohnpack provides nitrogen flushing for ampoules to assure reliable filling of humidity reactive filling materials.

Further processing of glass ampoules:

Generally, glass ampoules pose a logistic challenge. Depending on their use and how they are to be transported, the thin-walled glass ampoules must be assembled into a secure and functional application device. Lohnpack offers this service for any usage, for example, blistering of ampoules to be opened by breaking off the neck, including sealing with felt, or assembling into application sticks.

Ask the Lohnpack packaging experts about your requests and requirements for packaging glass ampoules.