Pouches, in particular, come in numerous variations. A big range of state-of-the-art, efficient assembly lines and machines enable Lohnpack to process this range of different pouches. Lohnpack offers different filling techniques for the following types of pouches:

- 3- and 4-sealed-edge pouches

- 2-component sealed-edge pouches

- 2-component mixing pouches with separating seam

- Sachets

- Stand-up pouches

- Powder sachets

- Spouted pouches

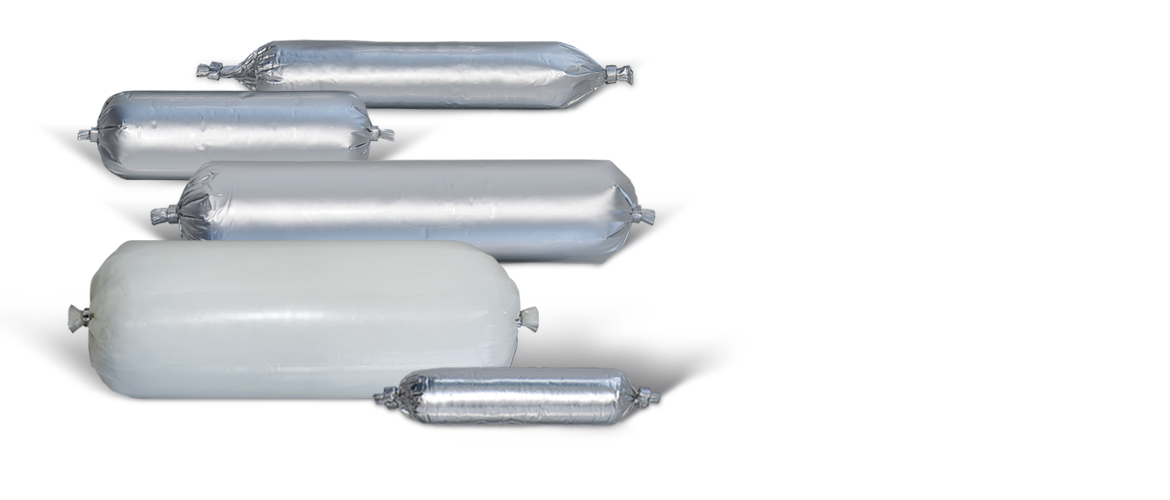

- Sausages

Various filling techniques enable us to fill pouches with materials that have either low or high viscosities, or that are in powder form.

These pouches can be further packaged in all conceivable ways.

The Lohnpack foil printing service can print pouches for you with up to four colors.