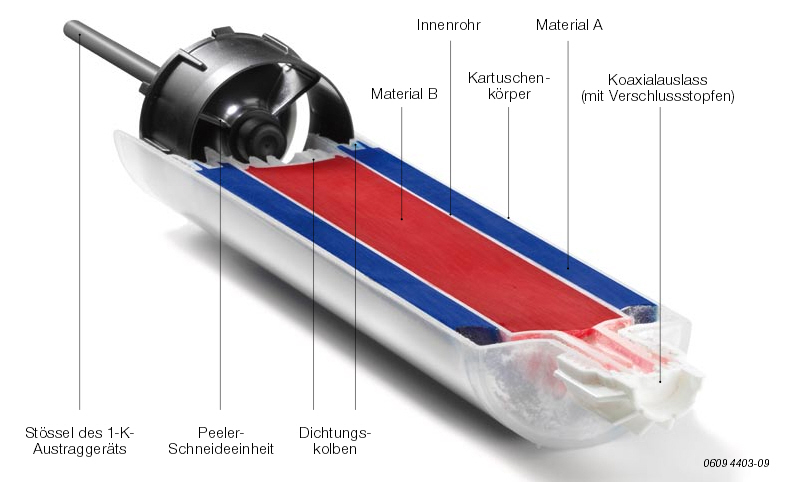

Coaxial and Peeler cartridges are 2-component cartridges. However, in contrast to SBS cartridges, the filling material is not arranged parallel but the cartridge consists of a cylindrical outer pipe and a therein placed cylindrical inner pipe. Consequently, there are two chambers arranged in a “pipe-in-pipe”-way (coaxial) that are separated from each other. They are filled with the two different components and sealed with a separate piston.

The Peeler cartridge is a special type of Coaxial cartridge. Its big advantage is that it can be pressed using any customary 1-component application gun. This is allowed by the use of so-called “Peeler cutting units” which are inserted into the cartridges after they are filled.