For many years, the fully automated filling of SBS cartridges has been part of Lohnpack’s core business. In close collaboration with incorporated HSV GmbH we continuously improve the filling technique of our high-performance special-purpose machines. HSV and Lohnpack are amongst today’s leading experts in building special-purpose machines for fully automated cartridge filling. Perfectly airless filling is critical to our engineers!

The jointly developed and HSV-built filling plants enjoy a superb reputation in the filling industry all over the world.

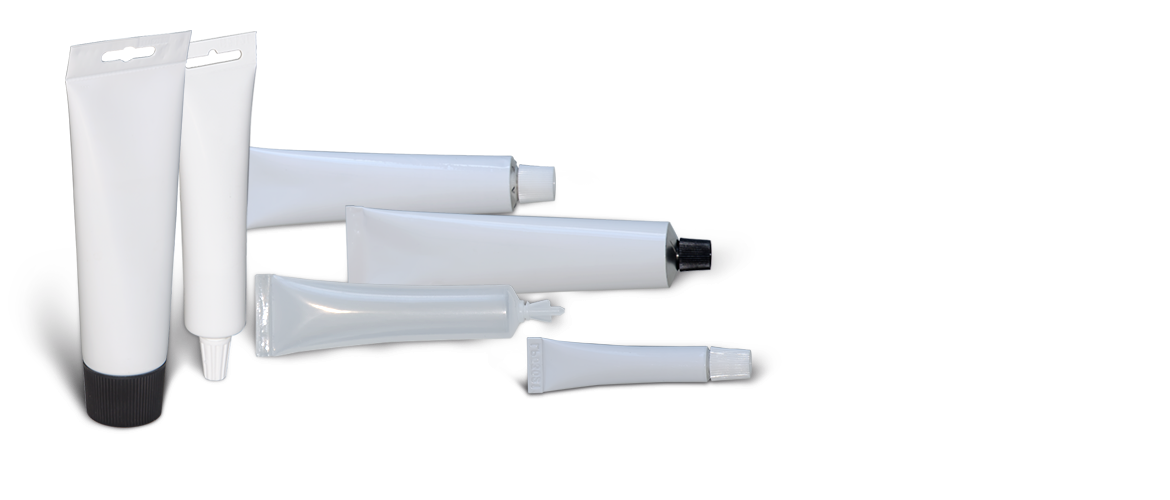

Lohnpack fills all cartridges existing at the market. Given that the specialized cartridges are supplied by the customer, special jobs can be completed.

Lohnpack can fill up to 50,000 cartridges a day thanks to its fully automated filling processes and comprehensive know-how.

Lohnpack’s services and advantages at a glance:

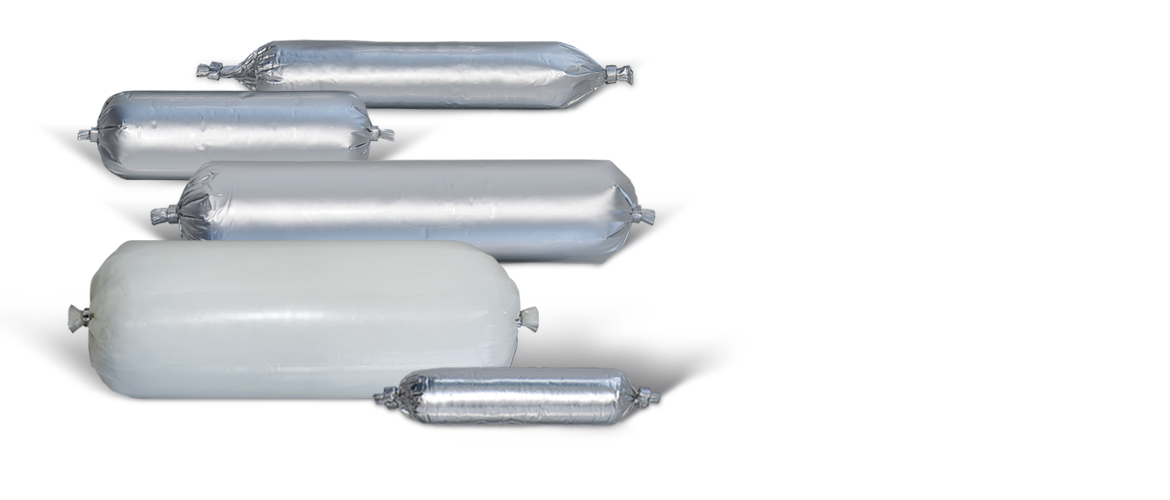

- Filling volumes ranging from 3 ml to 1500 ml

- Cartridges with different mixing ratios

- Mixing ratios of 1:1, 2:1, 3:1, 4:1, and 10:1

- Uncommon mixing ratios, i.e. 50:1

- Different materials, i.e. PP, PBT, or PA

- Consulting about filling requirements and application systems

- Filling of high-viscosity materials

- Filling of low-viscosity materials

- Ordinary filling from behind

- Filling from the front (depending on the cartridge type)

We support you in finding the best cartridge system or collaborate with the cartridge manufacturer of your choice.

Lohnpack offers a modern and powerful collection of filling machines. That way, many SBS cartridge types can be filled without further investments.

SBS application guns, which often are used in the DIY market, can be filled fully automated, including setting the plunger. Of course, special additional services like crimping the cartridge are possible.