Economical and reliable tube filling – once again, Lohnpack sets the benchmark with fully automated processes and filling technology.

The range of filling materials for tubes extends from harmless product groups such as acrylics to flammable or highly moisture-reactive filling materials.

Tube filling at a glance:

Convincing Facts:

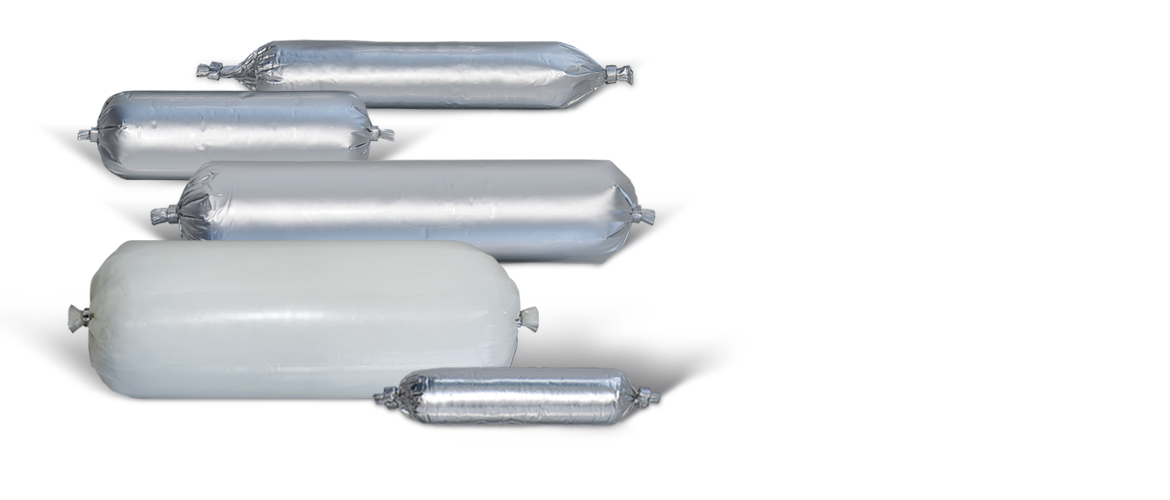

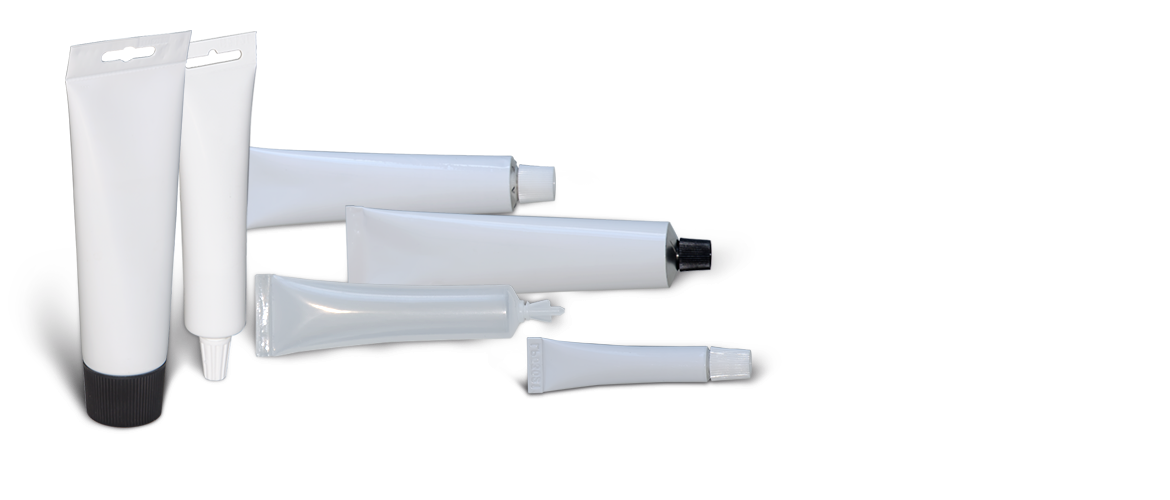

- Aluminum tubes

- Plastic tubes

- ABL (Aluminum Barrier Laminate) and PBL (Plastic Barrier Laminate) tubes

- Diameter 10-50 mm

- Filling volume of 1 ml to about 300 ml

- Daily capacity of up to 150,000 tubes

Services related to tube filling:

Our services include pre- and post-pressurizing with inert gas (e.g. Nitrogen), particularly for moisture-reactive filling materials, and the use of Hobbock- and drum presses for filling the entire range from liquid to highly viscous filling materials.

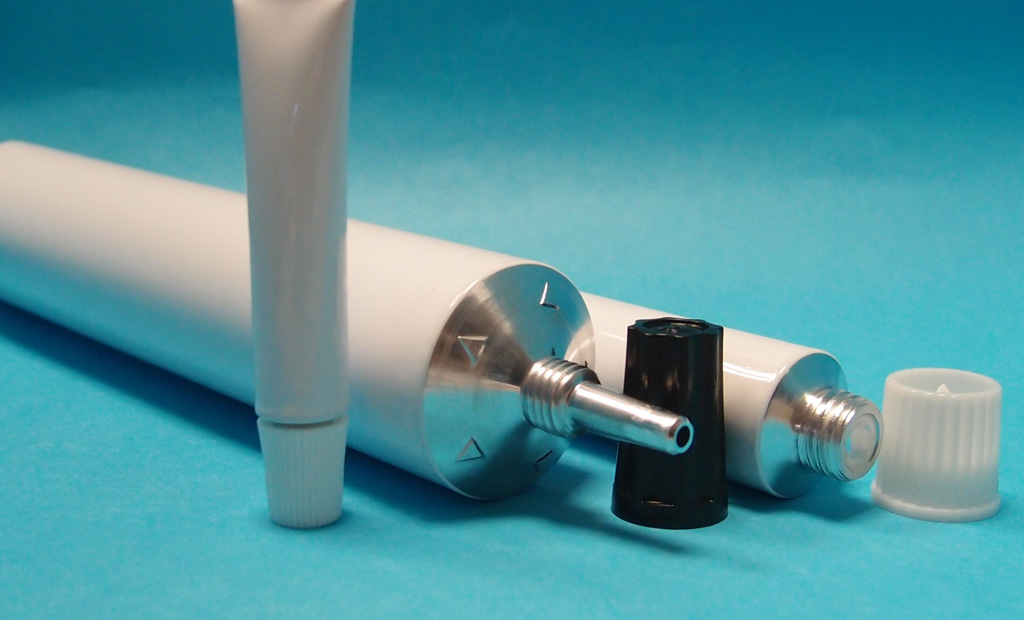

No matter what tube design or material, the tubes can be marked with a lot number in the fold/weld or printed on by inkjet in order to properly keep track of quality control.

Aluminum tubes can be sealed with different types of folds such as double or triple folds. Seam width is adjustable to the filling material, the length of the tube, and the printed image. Plastic and laminate tubes can be fitted with a euro hole if required. Integration of punching in the fully automatic process neither affects cycle time nor accrues additional costs.

Efficient, fully automated packaging:

By using fully automated cardboard packaging stations, tubes can be packaged in a timely manner. Automatic systems are also used to fold and insert operating instructions, as well as for tube labeling.

Often, tubes are used in the DIY market. Therefore, Lohnpack offers the blistering of tubes in both cardboard blisters and fully plastic blisters. Adding accessories such as nozzles or tube keys to the blistering process completes our services.